Facilities List

Mid Fab Customer Service

- Design support

- Technical advice and support

- Account management (relationship support)

- Consignment stock arrangements

- Scheduled delivery to your requirements

- Bespoke bill profiling

CAD/CAM Design & Development

Full CAD/CAM system

This facilitates off-line programming of CNC punching machines and CNC bending machines.

Customer information can be received in dxf, dwg, sat, step file formats

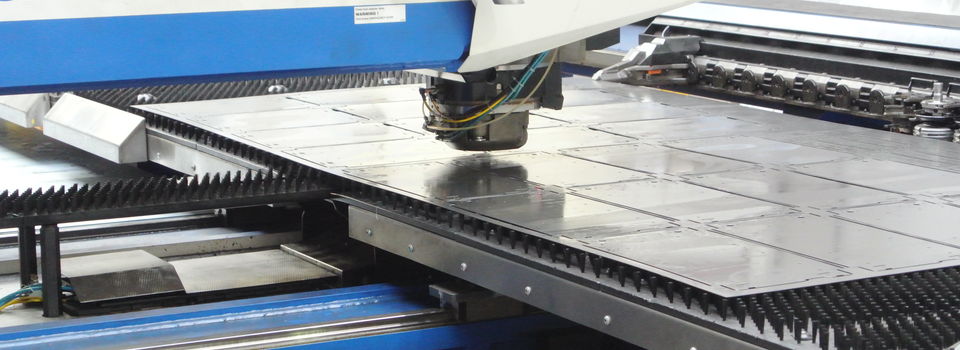

CNC Punching

Trumpf Trupunch 2020

Working range (X x Y)’ 2500 x 1250mm

Capacities:

- Max sheet thickness 6.4mm

- Max punching force 180kN

- Max workpiece weight 150kg

- Full 360⁰ rotation on all tools

- Sheetmaster load unload for lights out operation

- Forming, tapping and deburring functions

CNC Bending

1 x SAFAN e-brake 100T 3m

- Hydraulic top and bottom tool clamping

1 x Amada HFP 100-3

- Press type Hydraulic downstroking

- Bending pressure 100 tons

- Bending length 3110mm

- No of axis 7

Cutting

M-SHEAR Safan Guillotine

- Up to 6 mm thick mild steel plate

- Up to 4 mm thick stainless steel plate

- Up to 6 mm thick aluminium plate

Deburring

- Rasamax orbital deburring machines: steel and stainless steel

- Belt deburring: steel and stainless steel

- Soft wheel: aluminium

Silk Screen Printing

Full in-house silk screening facility

Welding

- 1 x MIG welding station

- 1 x PULSE MIG station

- 2 x TIG welding stations

- 2 x spot welders

Fasteners

- 1 x Haeger 824 – bowl fed, semi-automatic insertion machine

- 1 x Hartridge Sertabush 500 hydraulic insertion press

Finishing

We offer in-house stainless steel polishing. Natural and coloured anodising, powder coating and electro -plating are all available through local, reliable partners.

Assembly

Fully equipped, dedicated assembly facility bringing together sheet metal parts, plastics, fasteners, electrical components etc.

Delivery

Our centrally located facility in Birmingham is ideally placed in proximity to the UK’s major motorways providing a reliable delivery service, using our own fleet of vehicles, throughout the UK.